BlueAlp and RES partner to build Italy’s first 20kta advanced plastic recycling plant

Summary of key points:

- BlueAlp, a leading advanced recycling technology company, is partnering with waste management pioneer Recupero Etico Sostenible (RES) to realize the first industrial scale advanced recycling plant in Italy

- BlueAlp’s technology provides RES with a high value solution for plastic waste that is currently incinerated and landfilled. This addresses the demand for high quality recycled plastics such as food packaging

- RES’ experience in sorting and pretreatment of waste combined with BlueAlp’s existing detailed design of a commercial plant, makes this a fast-track project with operations expected to start in mid-2026.

8 May 2024: BlueAlp, a leading advanced recycling technology company, has signed an agreement with Recupero Etico Sostenibile S.p.A (RES), a waste management pioneer from Italy. BlueAlp will supply a technology license and will engineer, procure and fabricate the unit in its workshop in Eindhoven, The Netherlands. RES will own and operate the plant to process and convert 20kt of mixed plastic waste a year. This plant will be set up in Pettoranello del Molise in Italy and is estimated to be operational by mid-2026.

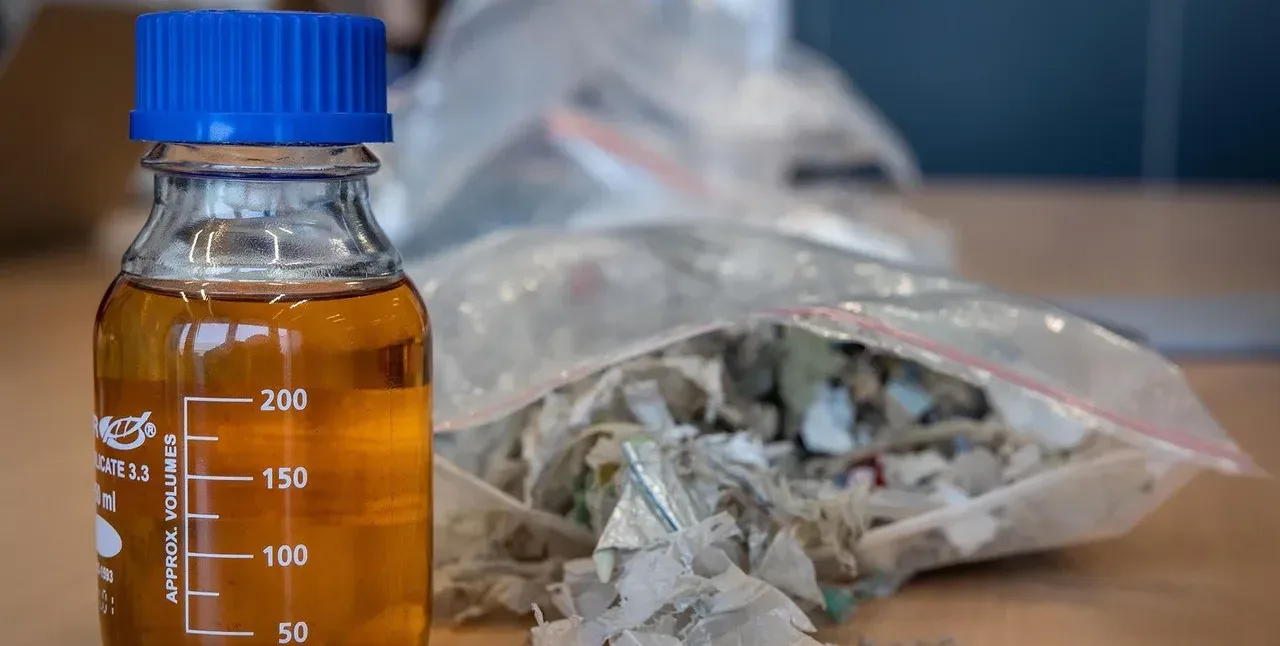

The industrial plant, based on BlueAlp’s patented pyrolysis technology, is the first in Italy in terms of size and production capacity and will be constructed next to RES’ existing mechanical recycling facilities. The plant will process waste that cannot be recycled mechanically, such as polyolefin film fractions. Waste plastics will be transformed back to their original form as pyrolysis oil. The oil can be used to replace raw materials in the virgin plastics value chain and chemical and petrochemical industries. This offers a response to the large demand for high quality recycled content solutions, for example the demand from FMCG players with ambitions to make plastic food packaging circular.

Valentijn de Neve, CEO of BlueAlp, says, “We are thrilled to partner with RES, as this marks a significant step towards making plastics truly circular. It is key that waste managers invest in plants and technology, giving another life to plastic waste that currently cannot be mechanically recycled. We are very proud to work with RES as they pioneer the materials transition, which perfectly aligns with BlueAlp’s ambition to accelerate plastic recycling. We aim to empower customers worldwide to embark on projects to recycle the plastics that are currently landfilled or incinerated.”

Antonio Lucio Valerio, CEO of RES S.p.A., says, “We are very proud to announce the signing of the agreement with BlueAlp that will lead to the construction of a new pyrolysis plant, the first in Italy in terms of size and investment. In line with the information and time schedule declared in the IPO, RES will be the first national operator able to close the waste cycle, from the initial collection to the sale of the raw material resulting from the plastics processing. All of this in a defined area, respecting the surrounding environment, demonstrating the potential that waste can have when innovation marries commitment to reducing oil dependency and promoting the responsible use of resources.”

BlueAlp is committed to giving plastic waste a new life with its continuous and scalable technology. The company’s advanced recycling technology continues to be the most sustainable and economically attractive technology to convert plastic waste into cracker feedstock.

The collaboration between RES and BlueAlp emphasizes that advanced recycling is beyond the phase of early adopters, and ready to tackle circularity at a global scale.

-

“This plastic now ends up in incineration, but out of 85% of it we can make new raw materials”. Trouw’s Hans Nauta and BlueAlp’s Valentijn de Neve had an interesting conversation about chemical recycling, the ambitions of the chemical industry and consumers of plastics in the value chain, and BlueAlp’s sustainability ambitions. The full article…

-

Financiele Telegraaf’s Gert van Harskamp interviewed BlueAlp CEO Valentijn de Neve about the potential of chemical recycling and BlueAlp’s ambitions to become the world’s number 1 technology provider, with the plan to have 60 installations built by 2025. To read the full article, click here (available in Dutch only).

-

The Hague − Shell Ventures BV and BlueAlp Holding BV today announced a strategic partnership to develop, scale and deploy BlueAlp’s plastic waste to chemical feedstock technology. The technology transforms plastic waste which is tough to recycle into a recycled feedstock (i.e. pyrolysis oil) that can be used to make sustainable chemicals. Shell has taken…

-

BlueAlp founder Chris van der Ree and CEO Valentijn de Neve had the opportunity to speak with Eindhoven’s Dagblad Merlijn van Dijk about the origins of BlueAlp. From Petrogas, which installations for the gas industry, towards the vision to contribute to accelerating plastic recycling with BlueAlp. Read more here about BlueAlp’s purpose, first customers and…